High-temperature heat pump units have become essential to modern energy utilization technologies, finding widespread applications across various industries such as industrial, agricultural, and commercial sectors. These units' unique performance and advantages are key in driving energy transitions and achieving energy conservation and emission reductions. This blog will explore the working principles, application areas, technical features, and future trends of high-temperature heat pump units.

How Do High-Temperature Heat Pump Units Work?

High-temperature heat pump units operate based on the principle of the reverse Carnot cycle. They use a small amount of electrical or thermal energy to absorb heat from a low-temperature source and transfer it to a high-temperature source. The process involves four key stages: evaporation, compression, condensation, and expansion. During evaporation, the refrigerant absorbs heat from the low-temperature source and turns into a low-pressure gas. This gas is then compressed into a high-temperature, high-pressure state. In the condensation stage, the gas releases its heat and turns into a liquid. Finally, during expansion, the liquid refrigerant is depressurized and returns to the evaporator, completing the cycle.

Where Are High-Temperature Heat Pump Units Applied?

1. Industrial Sector:

These units are used for heating, drying, and distillation processes, improving energy efficiency and reducing production costs. For example, in chemical, textile, and paper industries, high-temperature heat pump units can replace traditional boilers and electric heaters, providing clean and efficient energy.

2. Agricultural Sector:

High-temperature heat pump units are utilized in greenhouses, aquaculture, and drying processes, offering stable and reliable heat sources. In greenhouses, they maintain a constant temperature and humidity, promoting crop growth. In aquaculture, they provide optimal water temperatures for fish farming. For drying operations, they deliver fast and efficient results.

3. Commercial Sector:

These units are ideal for heating and hot water supply in hotels, hospitals, schools, and other public places. Their efficiency and environmental benefits make them a preferred choice for energy-saving and emission reduction in commercial settings.

What Are the Technical Features of High-Temperature Heat Pump Units?

1. Energy Efficiency:

High-temperature heat pump units leverage the reverse Carnot cycle to upgrade low-grade heat, resulting in high energy efficiency. Compared to traditional energy supply methods, they can save significant amounts of energy, reducing consumption costs.

2. Environmentally Friendly:

These units produce no pollutants during operation and are environmentally friendly. They also utilize renewable energy sources, such as solar and geothermal energy, reducing reliance on fossil fuels and helping to lower greenhouse gas emissions.

3. Reliable Operation:

Built with advanced control systems and high-quality materials, high-temperature heat pump units are known for their stability and reliability, even under harsh conditions.

4. Versatility:

High-temperature heat pump units can operate in various environmental conditions, including low temperatures, high temperatures, humidity, and dryness. They can also utilize multiple heat sources, such as solar and geothermal energy, for power.

What Is the Future of High-Temperature Heat Pump Units?

As the energy crisis intensifies and environmental awareness grows, high-temperature heat pump units will continue to see broader applications and development. The future of these units will focus on several key areas:

1. Improving Energy Efficiency:

System designs and manufacturing processes will be optimized to enhance the energy efficiency of high-temperature heat pump units, further reducing energy consumption costs.

2. Expanding Applications:

These units will find applications in more fields, such as food processing and wood drying, meeting various industries' diverse heat source needs.

3. Developing New Heat Sources: Research will explore new renewable energy sources, such as biomass and ocean energy, to further reduce reliance on fossil fuels.

4. Smart Control:

The integration of IoT and big data technologies will enable intelligent control and management of high-temperature heat pump units, improving operational efficiency and stability.

In conclusion, high-temperature heat pump units are crucial for driving energy transitions and achieving energy conservation and emission reduction. With ongoing technological advancements and expanding application areas, these units have a promising future ahead.

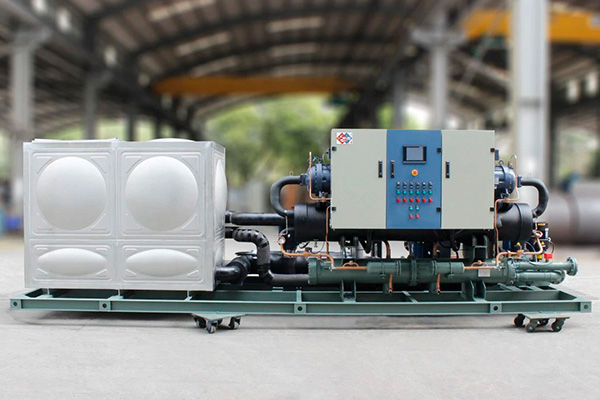

About H.Stars Group:

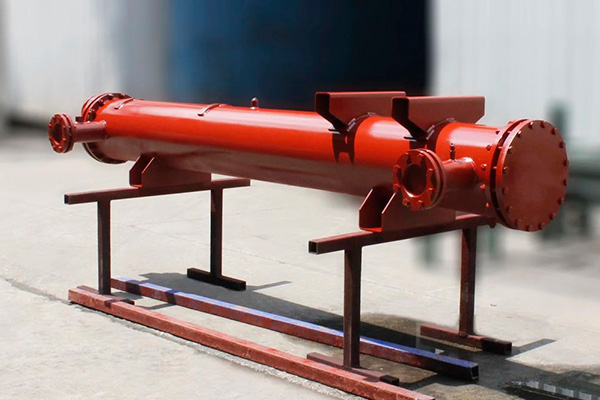

H.Stars Group,30 years Hongkong brand factory, manufactures a wide range of HVAC equipment: air-cooled chillers, water-cooled chillers, high-temperature heat pumps, AHU, and shell and tube heat exchangers supplying to worldwide 53+ countries. With H.Stars Hongkong brand recognition and 8 subsidiaries industrial chain, H.Stars Group has supplied HVAC products to 500 Fortune companies.

For more information ,welcome to contact at

+86 13922234648

sales@hstars.com.cn