Main Trends

Gourmet popcorn is gaining popularity all over the world, with the product set to become more than a treat at the movies and instead fully-fledged mainsteam trend. Over the years, we see a broadening of this to include other snacking occasions, instead of eating crisps or chocolate, people opt for popcorn. A lot of enquiries from people wanting to order and taste sweet popcorn. Therefore, gourmet popcorn sold briskly on the market. And it was a good opportunity to launch for food entrepreneurs.

How to launch gourmet popcorn?

The first step is to research local and national market trends to see where you can make a difference. Is there enough demand for gourmet popcorn in your area, for example, to justify opening a physical store? Furthermore, what flavors are popular in your area? You can season your popcorn with anything from caramel to bacon and chives if you want. Sell your popcorn on the internet to expand your business beyond the local market.

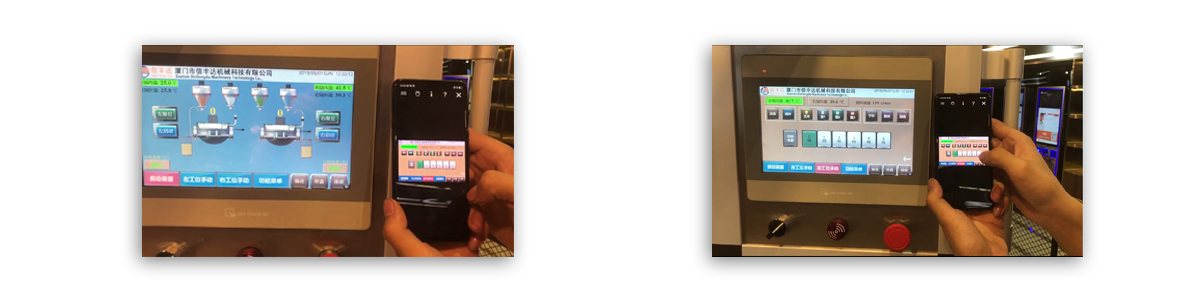

Second, once you’ve confirm the finished product, start with XFD

X-POP ingredients and XFD popcorn equipment can make your business easier.

X-POP Ingredients

Popcorn Oil: A blend of coconut and palm oil.

Corn Kernel: Butterfly Corn Kernels and Ball-Shape Corn Kernels (Includes Blue Butterfly, Red Butterfly, White Large Butterfly, Large Butterfly;: Extra Large Mushroom); Note: The quality of corn kernel will affect the yield of finished popcorn.

Popping Sugar: Popping oil, corn kernels and popping various flavor of sugar by oil popper directly; Note: X-POP popping sugar is anti-cooking for oil popper. X-POP Caramel, Apple Sugar, Strawberry Sugar, Orange Sugar and Blueberry Sugar is best-selling products for overseas customers. Welcome to inquire, we wholehearted for your service.

Coating Sugar: Coating pure popcorn with various flavor of sugar by caramelizer/coater directly; Note: Dedicated coating sugar for caramelizer/coater.

Coating Powder: Coating pure popcorn with various flavor of coating powder, such as cheese powder…

XFD Popcorn Equipment

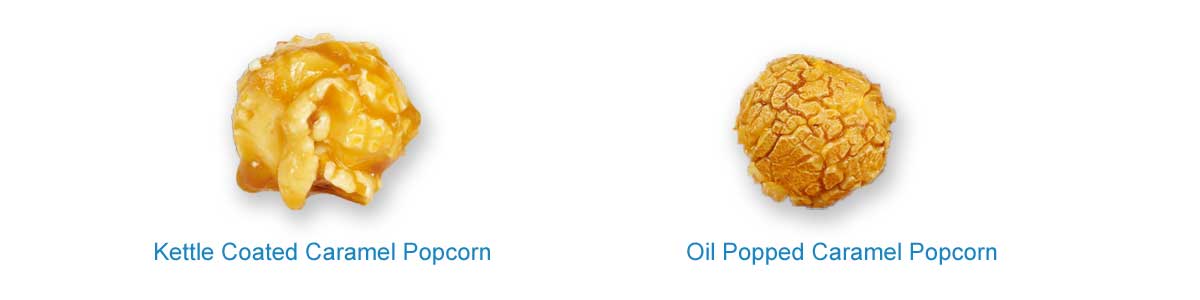

Oil popper: pop oil, corn kernels and various flavor of sugar together, making rainbow popcorn directly.

Air popper: pop corn kernels without oil and sugar, making pure popcorn directly.

Caramelizer/Coater: Most of time, coat pure popcorn by air popped with coating sugar or powder, making rainbow popcorn.

Note:

Here the big difference is that the caramel popcorn after air popped and coated with caramel is thicker than that after direct oil popping with caramel.

Select popcorn maker according to required capacity and process.

Third, selling packages of popcorn to customers. Popcorn may be sold in branded bags or tins.

Once you’re ready for gourmet popcorn business, don’t stop there! We believe that XFD popcorn equipment and service can exceed your expectationqs! If there is anything that can be of help, don’t hesitate to let us know!

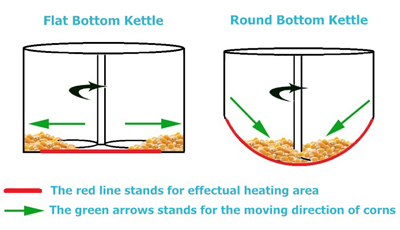

onehas big

advantages: The round bottom kettle could

avoid the centrifugal effect and ensure all the corns are in the middle of the

bottom (the effectual heating area) and well burst while the stirring rod rotating in the kettle, this directly influences

the production yield. The pelletizing ratio for jumbo (ball shape) is up to 90%-91%, which the traditional machine is only 80%-86%,

and the production yield is up to 99%. Beside, easily equipped with automatic

kettle-cleaning function by using the water droplets’ self-flow characteristic

and the stirring rod, these make it easy to clean.

onehas big

advantages: The round bottom kettle could

avoid the centrifugal effect and ensure all the corns are in the middle of the

bottom (the effectual heating area) and well burst while the stirring rod rotating in the kettle, this directly influences

the production yield. The pelletizing ratio for jumbo (ball shape) is up to 90%-91%, which the traditional machine is only 80%-86%,

and the production yield is up to 99%. Beside, easily equipped with automatic

kettle-cleaning function by using the water droplets’ self-flow characteristic

and the stirring rod, these make it easy to clean.