Bridge Mills A Comprehensive Guide to Precision Manufacturing

Introduction

Today, bridge mills are an indispensable tool for manufacturers in industries like aerospace, automotive, energy, and heavy machinery. Bridge mills are increasingly used as engineering designs become more complex and the need for enhanced stability, precision and flexibility to machine large and heavy workpieces to extremely tight tolerances continues. As a rigid overhead bridge structure with multi axis capabilities, bridge mills offer high precision cutting compared to traditional knee mills or gantry mills.

In this article, we will look at how bridge mills can produce continuous production of complex components that can’t be made with smaller machines. Whatever your R&D work or high volume manufacturing needs, bridge mills provide a flexible solution to maximize productivity and minimize errors.

What is a Bridge Mill?

A bridge mill uses a huge overhead bridge assembly to support the spindle and worktable instead of a column or gantry. The spindle is held as it moves in X, Y, and Z axes by the bridge as a rigid support arm and the worktable below is positioned relative to the cutting tool.

This overhead arrangement leaves the entire area beneath the bridge open for oversized parts and assemblies, allowing much larger workpieces than could fit on a traditional vertical mill. Bridge mills derive their name from the bridge-shaped beam that spans the work area.

The key components of a bridge mill are:

● Bridge - The large overhead beam that supports the spindle slide and provides damping against vibrations. It contains the mechanisms to position the spindle in X and Y.

● Spindle - The rotating shaft that holds the cutting tool. It is powered by a motor inside the spindle slide with up to 50 hp. High torque spindles allow fast removal of material.

● Table - The large stationary or moving platform that supports the workpiece. It provides a precision mounting surface and T-slot holds for clamps and fixtures.

● Column - A fixed vertical member at one end that helps support the bridge. The column may house controls or services.

● Saddle - The moving transverse component mounted to the underside of the bridge. It positions the spindle slide in the Y-axis across the width of the table.

● Spindle Slide - The carriage assembly that traverses back and forth along the bridge in the X-axis, positioning the spindle over the workpiece.

Compared to gantry or knee mills, bridge mills are significantly heavier and bulkier, with a main bridge that is much more rigid thanks to its continuous cast iron or welded steel overhead design. This mass and stability is crucial for absorbing cutting forces and dampening vibration that could compromise precision.

The rigid construction also minimizes deflection of the spindle during aggressive material removal, enabling much tighter tolerances. When machining large components made of tough materials like steel or titanium, the stability of a bridge mill is vital to achieve chatter-free results. Their overhead configuration also allows practically unlimited workpiece sizes.

Types of Bridge Mills

Bridge mills are available with different axis configurations and levels of automation to suit a wide range of applications:

2-Axis Bridge Mills

The simplest bridge mill design has two linear axes allowing motion in the X (longitudinal) and Y (transverse) directions. This provides positioning of the workpiece beneath the spindle for basic 2D operations like facing, drilling, boring, and end milling of flat surfaces. While limited in versatility, 2-axis bridge mills are an affordable option for high-volume production of large but basic parts, as their range of motion is sufficient for straightforward machining.

3-Axis Bridge Mills

A 3-axis bridge mill adds a Z-axis that raises and lowers the spindle vertically. This permits angled milling operations like helical interpolation, allowing the machining of bevels, tapers, contours, and angled features. The additional axis provides the ability to machine in 3 dimensions instead of just 2. Manufacturers gain greater flexibility to produce more complex components with a 3-axis bridge mill.

5-Axis Bridge Mills

On a 5-axis bridge mill, the spindle head tilts and rotates on two additional rotary axes in addition to moving linearly in X, Y, and Z. This enables the spindle to approach the workpiece from practically any orientation rather than just vertically. 5-axis motion facilitates high-precision machining of complex 3D surfaces and contours in a single setup, saving tremendously on time and cost. Many aerospace and impeller components require 5-axis milling due to their intricate blended or sculpted geometries.

Automated Bridge Mills

Modern computer numerical control (CNC) bridge mills allow all machining operations to be precisely programmed ahead of time. This allows push-button automation of repetitive cutting procedures with minimal operator intervention. The computer control precisely choreographs and executes tool paths for mass production. Automated tool changers, pallet changers, and robotic part load/unload systems can further enhance productivity for lights-out manufacturing across multiple shifts.

Key Features and Components of Bridge Mills

Massive Work Area

The cantilevered overhead design of a bridge mill leaves the entire area beneath the spindle open for oversized parts and assemblies. Common table sizes range from 5 x 10 ft up to 20 x 60 ft for gigantic components weighing over 100 tons. Huge motors drive the table through precision roller or hydrostatic ways. This expansive work zone minimizes setups by allowing batch machining of multiple large parts or entire weldments in a single fixture.

Rigid Bridge Assembly

Weighing up to 100,000 lb, the continuous overhead bridge utilizes a rigid box-way construction that resists deflection and damps vibration far better than jointed column or gantry mills. This stability prevents tool chatter, allows heavier cuts, and enables highly accurate motion of the spindle carriage across wide spans. Even minimal vibration can degrade precision and surface finish.

Powerful Spindles

High torque spindles up to 50 hp are common on bridge mills to power through hard alloys and remove material quickly from large parts. Higher rotational speeds up to 15,000 rpm provide ideal cutting speeds for optimized tool life and surface finish. The spindle cartridge is preloaded for thermal stability and minimal runout.

Precise Positioning

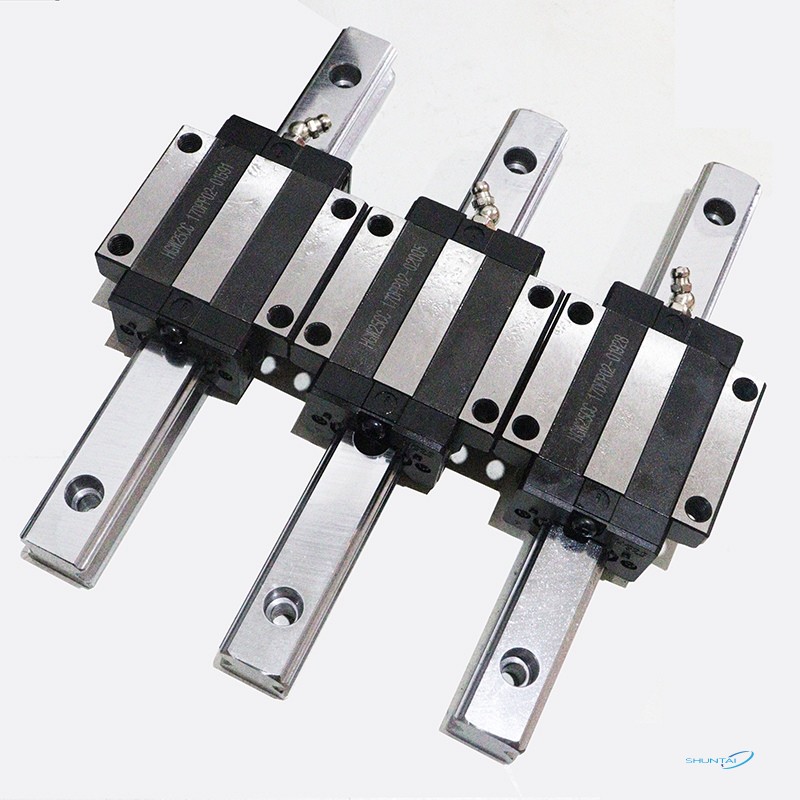

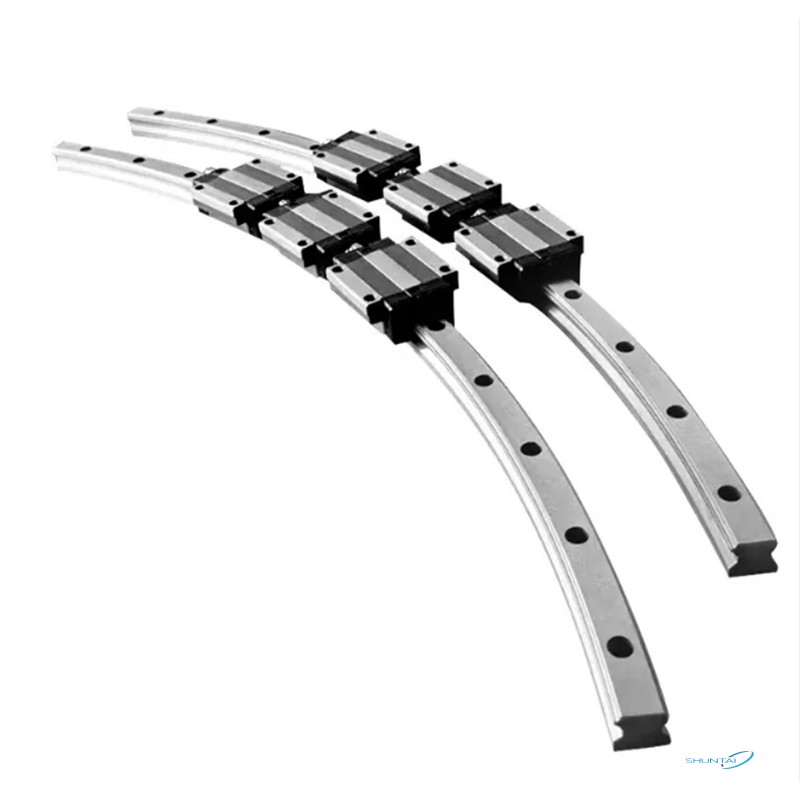

Ballscrews on the X, Y, and Z axes have high lead precision for accurate positioning and repeatability within 0.001”. Backlash is eliminated through preloading. Precision ground box ways or linear guides maintain tight geometrical tolerances when moving heavy components.

Multi-axis Capability

Optional rotary axes expand the range of possible milling operations by allowing angled cuts and 5-axis interpolated motion. Tilting the spindle facilitates machining of complex 3D contours, sculpted surfaces, and intricate blade geometries in a single setup.

Automated Features

Bridge mills equipped with CNC, tool changers, pallet shuttles, robotic part handling, automatic lubrication, and more enable lights-out manufacturing for maximum productivity. Hundreds of parts can be machined without operator intervention across multiple shifts.

Applications of Bridge Mills

Aerospace Industry

Aircraft construction relies on large monolithic components like wings, frames, and bulkheads milled from aluminum, titanium, or composites. Landing gear, turbines, transmission housings, and other assemblies also demand high precision. Bridge mills offer the work envelope and accuracy needed for these high-value aerospace components with delicate instrumentation.

Automotive Industry

Automakers machine engine blocks, cylinder heads, crankshafts, transmission cases, axles, wheels, and body components from large steel or aluminum castings and weldments. Bridge mills maintain tight tolerances on these heavy parts while removing material quickly. Their high rigidity suits the noisy environment.

Heavy Machinery

Massive excavator booms, bulldozer track links, hydraulic cylinders, press frames, and other oversize parts require stable bridge mills to withstand vibrations inherent in heavy machining. They excel at removing substantial material from thick castings and fabrications.

Mold Making

Larger injection molds, die cast dies, and foundry patterns demand the precision of bridge mills to accurately produce contoured cavities without distortion. Their work volume readily accommodates even enormous 400-ton plastic or metal molds. Tight process control optimizes molded part quality.

Energy Industry

Turbines, compressors, reactors, valves, offshore platform components, and more leverage the long travels and precision of bridge mills during manufacturing. The mills maintain quality standards for these expensive parts operating in extreme conditions.

Benefits of Using Bridge Mills

Precision

The stability provided by the rigid overhead bridge enables extremely tight tolerances, even when machining large parts from vibration-prone materials like titanium or nickel alloys. Chatter is avoided, allowing smooth, accurate cuts.

Versatility

Available in different sizes and with varying axis configurations, bridge mills can handle a wider range of materials and part geometries compared to smaller mills. Their heavy-duty build allows machining everything from stainless steel to composites.

Cost Savings

While bridge mills require a greater upfront investment, they maximize productivity and minimize operating costs on large components. Their ability to consolidate several operations in one setup saves tremendously on fixtures, tooling, programming, and quality inspections.

Improved Throughput

Continuous cuts across expansive work zones result in shorter cycle times. Pallet changers and part loading/unloading automation further boost throughput for high-volume production across multiple shifts, improving asset utilization.

Reliability

Industrial bridge mills are built for round-the-clock operation in harsh conditions. They stand up to heavy use with minimal downtime. Many operate reliably for decades after proper installation, maintenance, and training.

How to Choose the Right Bridge Mill

Workpiece Size

Consider current and future maximum part dimensions to ensure the mill will accommodate them with room for fixturing and tooling. A too-small machine will severely limit capability.

Axis Configuration

The type and complexity of required milling operations determines the ideal number of axes. 5-axis mills offer the most application flexibility and reduce setups through multisided machining but are costlier.

Spindle Power

Ample spindle power prevents slowdowns or stalling when removing substantial material. Higher torque spindles with 15,000+ rpm allow faster hogging and finishing feeds/speeds. Ensure power meets demands.

Precision Standards

More expensive machines generally offer greater accuracy through more precise ballscrews, way quality, vibration dampening, and thermal stability. Evaluate precision needs carefully.

Automation Plans

Consider pallet changers, robotic part handling, tool changers, CNC programming, and other automation upfront rather than difficult retrofitting later. This optimizes lights-out production.

Service and Support

Reliable local service and technical support will maximize uptime and productivity. Ensure the machine builder has a proven reputation for quality and customer care.

Common Challenges with Bridge Mills

Vibration Control

Excessive vibration during heavy duty milling can cause chatter, accuracy issues, poor surface finish, and reduced tool life. Careful fixturing, balanced tooling, adaptive feed control, and smooth ramping of spindle speed help mitigate vibrations.

Thermal Effects

Frictional heat during machining causes components to expand, altering dimensions. Chillers and coolant systems counteract thermal growth. CNCs can also compensate by altering cutter paths based on temperature sensors.

Tool Wear

Abrasive alloys quickly degrade cutting tools. Advanced tool materials, coatings, proper selection of speeds/feeds, and indexed inserts all help combat wear. In-process gauging can automatically adjust for loss of tool diameter.

Maintenance Needs

Bridge mills have thousands of moving components requiring regular lubrication, inspection, and service for optimal reliability. Skilled technicians should track and perform preventative maintenance.

Space Constraints

Bridge mills have massive footprints, heights, and weights demanding substantial floor space, reinforced foundations, and rigging equipment. Facilities must carefully plan layouts to accommodate their bulk.

Future Trends in Bridge Mill Technology

Automation and AI Integration

Smart machine monitoring with artificial intelligence promises even greater productivity through predictive maintenance, troubleshooting, adaptive control, and automated inspection. The mills will become self-optimizing.

Multi-tasking Capability

Next-generation bridge mills will incorporate turning, grinding, drilling, tapping, and other capabilities on one platform for complete production of complex parts in a single setup. Hybrid machine tools will continue gaining traction.

Advanced Materials

More manufacturers are adopting hard-to-machine materials like titanium, Inconel, and composites. Future spindles, tools, programming, and controls will be optimized for these exotic materials.

Sustainable Design

Eco-friendly lubrication systems, intelligent sleep modes, hybrid drives, and through-spindle coolant will be incorporated for energy and fluid efficiency. Bridge mills are getting greener.

Conclusion

Bridge mills with their huge work areas, superb stability and multi axis flexibility allow manufacturers to increase precision, productivity and agility when making large complex parts. They are leaders in optimizing output, quality and consistency for critical aerospace, automotive and heavy industry parts.

Bridge mills are a greater upfront investment, but the long term savings of reduced setups, improved workflow and increased throughput are huge. Bridge mills will only grow in strategic importance as engineering components become bigger and more sophisticated. Strong consideration should be given by companies seeking to maximize manufacturing capabilities, capacity, and competitiveness to the use of bridge mills. Their advantages are unique, enabling manufacturers to do what is not possible on smaller machines.