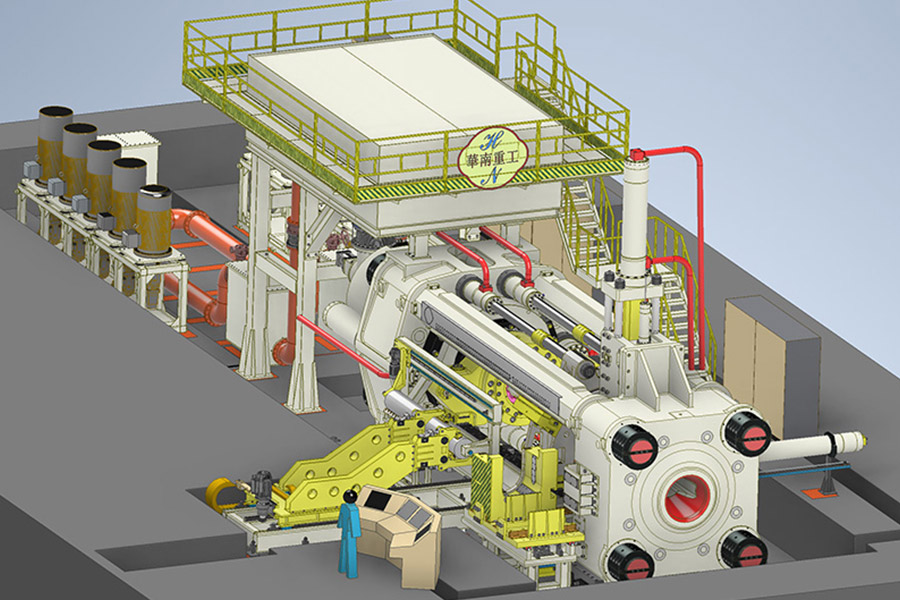

Aluminum Extrusion press for prestressed composite frames

A solid extruder structure is a prerequisite for ensuring the performance of the extruder. After being used for a period of time, many Aluminum extrusion machine become loose, the interfaces age, and the cylinders bend, resulting in deformation and unstable quality during the aluminum extrusion production process. In fact, the main reason is that the extruder as a whole is not strong enough.

The stress during the operation of the extruder is very large, and our extruders mostly adopt a prestressed composite frame structure, which is composed of a high-thickness integral front beam, a high-thickness rear beam, and a square prestressed sleeve to form a closed The prestressed composite frame uses a special hydraulic preloading tool to apply an overpressure tensile load to the entire length of the tie rod, and at the same time applies compressive stress to the pressure sleeve, so that the entire frame is in a stress pretightened state, and the tension column prestress is 115% of the maximum load. above. For example, our 7500-ton hydraulic extrusion press has a front beam thickness of 1950mm made of ZG35Mn, a rear beam thickness of 1800mm (material ZG35Mn), and a square pre-applied sleeve (material ZG35). It can make it bear force better, which is also an important reason for the long service life of the extrusion machine.

Other advantages of prestressed composite frames

1. The center distance of the four stressed tie rods of the frame is symmetrical to the center of the press, so that the entire frame is stressed evenly. The main reason why the quality of aluminum materials produced is stable or unstable is whether the force is uniform. Only by maintaining uniform force can the overall density of the aluminum material be uniform, thereby improving the accuracy of extruded products.

2. The prestressed composite frame frame has a larger bending section, which makes the frame elongation and bending deformation smaller under the action of extrusion force. Therefore, the extrusion beam and the lower part of the extrusion tube can be fixed on the lower frame. The horizontal and vertical guide rails are very convenient for centering adjustment between the extrusion beam, extrusion barrel and mold. The upper frame can be used as an X-shaped moving guide rail for the extrusion barrel. On the premise of ensuring the stability of the machinery, the available space is used to reduce the space occupancy of the machinery.

3. There are two sets of elastic anchoring devices and foundation anchors on the lower part of the rear beam to make the rear beam fixed reliably.

After many years of production experience and continuous improvement based on customer feedback, our extrusion press is currently one of the most stable extruders on the Chinese market and one of the longest-lasting Aluminum extrusion machine.