Manufacturing and machining of parts require that they be produced accurately and repeatedly, so CNC (computer numerical control) machines are significant. The most widely used types of CNC machines are gantry and vertical machining centers. In terms of the kinds of applications, both have strengths and weaknesses. This article examines the essential points of difference between these two machines in order to determine which is most suited for various machine requirements.

What is a Gantry CNC Machine?

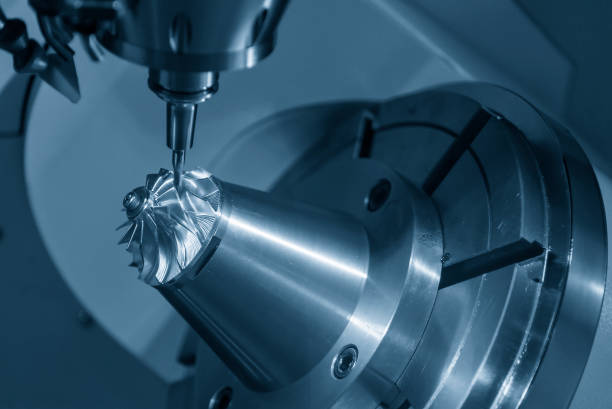

The gantry CNC machine comprises a horizontal beam by which the workspace is spanned and mounted on two side supports. This beam includes a spindle or cutting tool attachment, which can be moved in three linear axes (X, Y, Z). This offers accurate positioning over a great working area for finishing large parts.

How Gantry CNC Machine Works?

A gantry CNC machine has a bridge-like frame called a gantry. This gantry has rails that allow a spindle head to move left-to-right and forwards-backwards. The spindle head holds the cutting tool and moves along the X and Y axes. The cutting tool is lowered up and down on the Z-axis to touch the workpiece. The motion of the spindle head is controlled precisely by a computer which follows a programmed path. This allows the gantry CNC machine to cut, drill, and mill large metal or wood parts accurately by precisely positioning the spinning cutting tool according to CNC code instructions loaded into the computer. Gantry construction provides stability for handling big parts.

Key Features Gantry CNC

Large Work Envelope

One prominent feature is the large work envelope. The gantry frame structure allows for linear travel of multiple meters in both the X and Y axes. This oversized work zone is suited for machining extremely large parts beyond the capacity of typical CNC machines. On extended-length gantry machines, parts with lengths over 5 meters can be handled.CNC

Unobstructed Part Access

Another notable feature is the unobstructed part access provided by the horizontal orientation. There is clear access without obstructions around the work area, so workers can easily load and unload very large parts from all sides. This unimpeded multi-sided part access aids workflow.

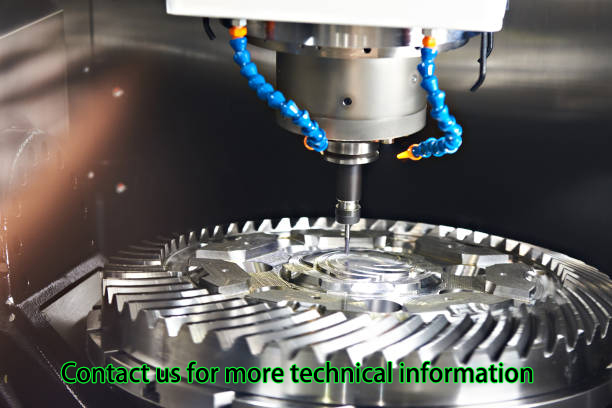

Powerful Spindle Motors

Gantry CNC machines are also equipped with powerful spindle motors, usually from 10 horsepower to over 50 HP. The high, low-end torque from these powerful spindles allows aggressive metal removal. The dynamic and rigid construction can handle the heavy cutting forces exerted during intense drilling and milling operations.

Diverse Machining Capabilities

Finally, gantry CNC machines have diverse machining capabilities, making them well-matched for applications like plasma cutting, abrasive waterjet cutting, routing, and milling. The gantry architecture provides stability for accurate machining over the large work zone. Changes in tooling also allow the creating different part geometries using the same machine.

Uses of Gantry CNC Machines

Gantry CNC machines are commonly used in certain machining applications that utilize their large work volumes and powerful metal-cutting capabilities. The major categories of applications are:

Machining Oversized Metal Components

Many types of heavy equipment and vehicles have very bulky parts that exceed the bed size of regular CNCs. Gantry CNC machines have work zones matching these jumbo dimensions for machining oversized metal pieces.

Vehicle frames, bodies, agriculture equipment parts, ship hull sections, and structural construction components can have lengths over 5 meters. The meter plus capacity along the X and Y axes of gantry CNC machines enables the making of even such long metal parts.

Handling and Fabricating Large Woodworking Pieces

The woodworking industry requires the capability to machine huge wooden parts efficiently. Kitchen and display cabinets, giant furniture, big entrance doors, and building wood framing need abundant machining envelopes.

Nesting software helps optimize cutting when machining multiple wooden workpieces from sheet goods. Gantry machines have a rugged, abrasion-resistant construction to withstand all the wood chips and dust created.

Cutting Operations on Plate Stocks

Processes like plasma arc cutting and abrasive waterjet cutting require smoothly moving the cutting head along X and Y axes to achieve curvy patterns on plate material.

Gantry CNC machines offer the layout and robust build to move substantial weights smoothly across these lateral axes when flame-cutting steel plates or water jet-slicing stacked metal layers.

Advantages of Gantry CNC Machines

Oversized Work Envelope

Gantry CNC machines offer large working ranges along X, Y, and Z linear axes. This enables handling extra-large metal or wood parts exceeding the capacity of typical CNCs. Customizable to get bigger.

Minimal Design Deflection

The reinforced gantry frame paired with thick overhead beams and supports results in a robust, rigid structure. This dynamic stability retains accuracy when removing high metal cuts.

Unhindered Multi-Sided Access

The horizontal layout allows the loading of oversized parts from all sides without impediments. Workers can conveniently reach the entire work zone, improving workflow.

High Power Cutting Ability

Gantry CNC machines can integrate 50 HP or higher spindle power to rotationally drive large-diameter cutting tools at high torques vital for tapping, boring, and milling.

Disadvantages of Gantry CNC Machines

· The huge structure takes up a lot of shop floor space.

· High initial purchasing cost.

· It is not very versatile for small intricate components.

· It is limited in diagonal cutting ability.

What is a Vertical Machining Center

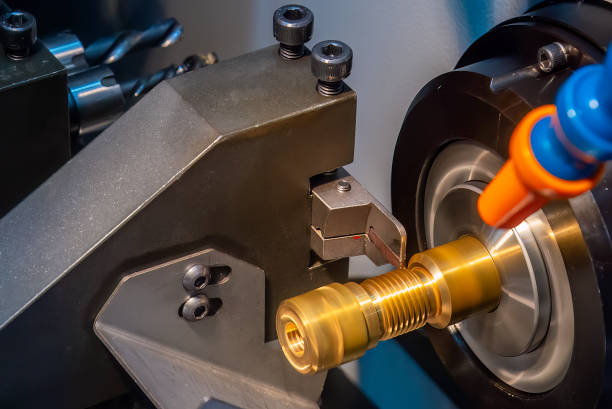

A Vertical Machining Center (VMC) refers to a Computer Numerical Control machine with a vertically oriented spindle axis. This allows the machining operations like milling, drilling, tapping, boring, etc, to be performed on a horizontally positioned workpiece.

The key parts of a VMC include the tool changers, tool magazines, CNC controller, cutting tools, coolant system, and the X, Y, and Z axis guideways. The tool magazine allows for automatic changes in cutting tools.

How Vertical Machining Center Works?

A vertical machining center has a spindle oriented vertically above the work table. The metal or plastic workpiece is secured to this table and can move back and forth on the Y-axis and in-out on the X-axis. The cutting tool attaches to the downward-pointing spindle. In CNC operation, the machine precisely controls the position of the table under the spindle, allowing the rotating cutting tool to mill and drill holes in the fixed workpiece. To accomplish machining operations, the Z-axis control lowers the spinning cutter into the workpiece at varying depths. Precision lead screws on the X, Y, and Z axes position the work area in relation to the cutter following computer numeric control instructions. This 3-axis motion allows versatile machining.

Key Features of Vertical Machining Centers

Compact Machinery Layout

The vertical orientation where the spindle coupling sits above the work table minimizes the machine footprint. This compact architecture fits production floors with space constraints.

Automatic Tool Changer

An automated tool changer assembly is commonly integrated within the machine enclosure for swapping cutting tools as needed. Reduces manual operator involvement.

Enclosed Machining Compartment

A fixed or sliding door seals the working area. This controls loose metal chips/coolant containment and reduces noise emission to the shop floor for a better work environment.

Programmable Coolant Nozzles

Smart coolant nozzles direct high-pressure coolant streams to critical areas like the tooltip and machining interface via the CNC program, improving heat control and chip flushing.

Direct Spindle Drive

The vertical spindle assembly connects directly to the high-torque motor without mechanical transmission loss. This enables optimal power transfer for heavy-duty cutting.

Uses of Vertical Machining Centers

Precision Metal Cutting

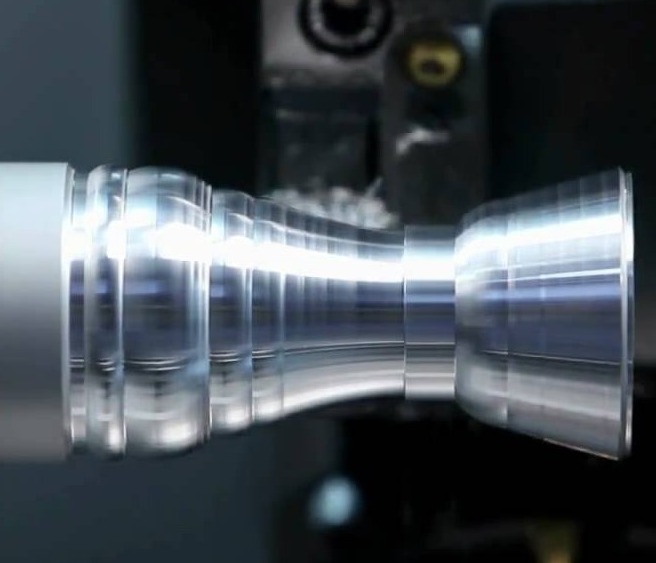

The rigid column design and direct spindle drive enable vertical machining centers to mill, drill, bore, and tap steel, aluminum, and titanium accurately with tight tolerances. Aerospace and medical parts often specify precision requirements.

Short Production Runs

Quick changeover between jobs makes a VMC suitable for small batch production rather than high volume long runs. Pallet pools with queued workpieces allow automated job shop workflows.

Completing Secondary Operations

After initial fabrication processes like casting or forging, vertical machining performs secondary refinements like surface finishing, hole drilling/boring, and profile milling to finish components.

Handing Varied Materials

From tough aerospace alloys, cast iron, and hardened tool steels to softer non-ferrous metals, vertical mills adapt via spindle speeds, tooling changes, coolant pressure, etc.

Advantages of VMCs

Space Saving Footprint

The vertical layout where the spindle sits above the work table minimizes the machine footprint for crowded shop floors. Takes less area than a horizontal machining center.

Fully Enclosed Work Zone

Having an enclosed machining compartment prevents debris like metal chips and coolant mist from dispersing externally. This helps maintain clean shop air quality.

Rigid Column Design

Column support for spindle plus minimal overhang or cantilever contributes to a rigid build. This stiffness enables more aggressive material removal than cantilever-style horizontal mills.

Efficient Chip Removal

With a vertical spindle pointing downwards into the work zone, chips naturally fall away without re-cutting. Automatic chip removal systems can also integrate more easily.

Automation Capability

A vertical machining center's small footprint and methodical compartment layout suit part pallet automation. Worker involvement is minimized with automated work part loading/unloading.

Multi-Face Machining

The rotating table indexes each work face towards the cutter for sequential machining without refixturing, decreasing handling time. All required milling, drilling, and tapping happen in one setup.

Disadvantages of VMCs

· Limited X and Y travel restricts maximum part dimensions

· Vertical spindle limits machining of very tall parts

· Higher energy consumption than horizontal CNC machines

· Cannot handle extremely long parts

Comparing Key Specifications

When comparing gantry CNC machines vs. VMCs, some key factors to analyze are:

Work Envelope Size

Gantry CNC machines offer a large work envelope with multiple-meter X-Y travels to handle big parts. Vertical machining center travels max out at around 2500 x 1200mm.

Structural Rigidity

The gantry uses thick overhead beams spanning heavy supports for excellent stiffness. VMC cantilevers and moving columns may allow slight deviations under loads.

Machining Versatility

VMCs adapt to varied materials and operations like precision boring and contouring. Gantries focus on high-force drilling/tapping or moving big parts across a large area.

Automation Suitability

A VMC's compact footprint suits part pallet automation. Gantry's vast work zone makes it harder to integrate part-loading automation.

Which is Better Suited?

After analyzing the differing strengths between gantry CNC machines and vertical machining centers, some general recommendations can be made regarding which is better selected for specific machining requirements:

When to Choose a Gantry CNC Machine?

If the machined parts are oversized with one or both dimensions exceeding a VMC's typical 1500-2000mm x-axis travel, then movement along a gantry's extended X and Y linear rails is better suited for positioning under the cutter. Gantry machines with travel over 5 meters are readily available.

The reinforced gantry provides rigidity for heavy metal-cutting applications where huge amounts of steel, titanium, or cast iron need high torque removal. Deflection is minimized despite dynamic cutting forces.

If the worked material requires clearance around all sides rather than secure fixturing, such as welding large frames or plasma-cutting plate stock, then the open horizontal orientation of the gantry facilitates multi-site access.

When to Select a Vertical Machining Center?

When factory floor space utilization needs optimizing, a VMC's compact footprint that takes less area than a hulking gantry system allows packing more machines into limited square footage.

If the production process requires various milling, drilling, and boring operations on multiple workpiece faces, the rotary table indexing of vertical machining centers allows sequential completion of integrated machining in one fixture setup.

When machining parameters call for tight tolerances, precision boring, intricate contours, or fine surface finishes, a VMC's rigidity and faster processor suit rapid yet accurate interpolation of cutting tool motion.

Summing It Up

Gantry CNC machines and Vertical Machining Centers both serve important but distinct CNC machining roles. Their configurations suit applications based on work zone requirements, machine rigidity, automation needs, and shop floor space constraints. Carefully analyzing the specifications and capabilities of each will determine which solution best fits your production environment.