Metal engraving is the process of carving or etching designs, text, or patterns into metal surfaces. This technique has been used for centuries in art, manufacturing, and marking. It involves creating precise, detailed engravings on materials like steel, aluminum, brass, and more.

Precision is crucial in metal engraving. Industries such as aerospace, automotive, jewelry, and electronics rely on accurate engravings for product identification, branding, and functional purposes. Even the smallest errors can lead to costly mistakes and affect product performance, which is why precision is paramount.

CNC (Computer Numerical Control) technology has revolutionized the metal engraving process. Traditionally, engraving required manual labor and high skill levels. CNC machines automate the process, allowing for high-speed, high-precision engraving. With CNC, designs can be programmed into the machine, ensuring consistency across multiple pieces. The machine moves along multiple axes, carving intricate designs with incredible accuracy.

CNC technology has greatly improved the efficiency and versatility of metal engraving, making it accessible for both small-scale and large-scale production. Whether it’s for creating intricate patterns, serial numbers, or logos, CNC machines provide the precision needed for professional-quality engravings.

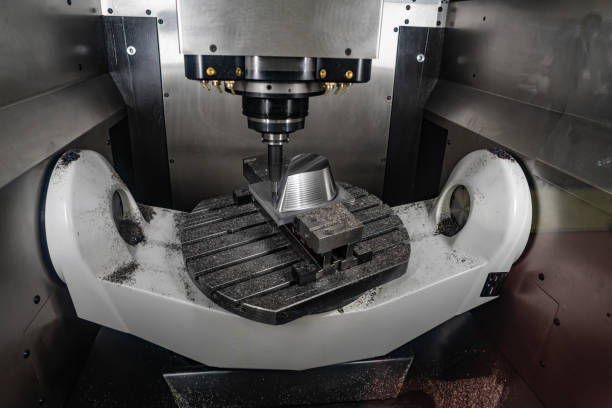

CNC Machines in Metal Engraving

CNC machines automate the metal engraving process by following programmed instructions. The operator inputs the design into the system, and the machine uses precise movements to engrave or etch the metal surface. This eliminates manual errors and enhances consistency.

Types of CNC Machines for Engraving

CNC milling machines are commonly used for engraving on hard metals. These machines use rotating tools to carve intricate designs with high accuracy. On the other hand, CNC routers are suited for softer metals and larger workpieces. They also follow similar principles but are often used for engraving on flat surfaces.

Benefits of Using CNC for Metal Engraving

Precision is a key advantage of CNC machines. They can create detailed, intricate designs with exceptional accuracy. Efficiency is another benefit, as CNC machines significantly speed up the engraving process. Lastly, repeatability is guaranteed, ensuring that the same design is engraved consistently across multiple items, making it ideal for both custom and mass production.

Key Components of CNC Machines for Engraving

CNC Engravers and Their Features

CNC engravers are specialized machines designed for precision engraving on metal surfaces. They are equipped with advanced features such as high-speed spindles, customizable tool settings, and precise movement controls. These machines can engrave detailed designs, logos, or patterns with high accuracy, making them suitable for a wide range of metalworking applications.

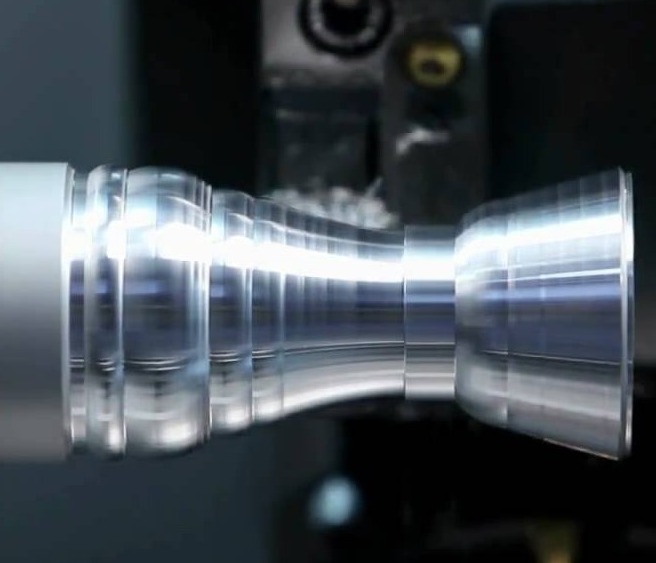

Spindle and Tool Types Used in Metal Engraving

The spindle is the heart of any CNC machine used for engraving. It holds and rotates the cutting tool, which directly impacts the quality of the engraving. For metal engraving, spindles are typically high-speed and robust to handle tougher materials. Common tool types include end mills, ball nose cutters, and diamond-tipped tools, each serving specific engraving purposes such as fine detailing or larger, more aggressive cuts.

Role of CAD/CAM Software in Preparing Metal Engraving Designs

CAD (Computer-Aided Design) software is used to create the intricate designs that will be engraved. The software allows the user to model the design in 2D or 3D. CAM (Computer-Aided Manufacturing) software then translates these designs into machine-readable code, guiding the CNC engraver in executing the engraving. This combination of CAD and CAM ensures that designs are accurate, repeatable, and executed with high precision.

Advantages of CNC Metal Engraving

CNC metal engraving offers exceptional precision, far surpassing manual engraving methods. The computer-controlled nature of CNC machines ensures that every cut is made with exact measurements, minimizing human error. This high level of accuracy is essential for industries that require fine details, such as electronics, aerospace, and jewelry, where even the smallest deviations can lead to significant issues.

Faster Turnaround Times for Large-Scale Production

CNC machines dramatically reduce the time required for metal engraving, especially for large-scale production. Unlike manual engraving, which is time-consuming and labor-intensive, CNC machines can engrave multiple pieces simultaneously, increasing throughput. The automated process allows manufacturers to complete high-volume projects in a fraction of the time, which is crucial in industries that rely on quick turnaround times.

Ability to Create Intricate Designs and Detailed Patterns

One of the key advantages of CNC metal engraving is the ability to produce highly intricate and detailed designs. CNC technology allows for the creation of complex patterns that would be extremely difficult or impossible to achieve manually. Whether it’s delicate engravings or three-dimensional designs, CNC machines offer limitless possibilities for customization, providing superior results for custom products, art, or branding.

Consistency and Repeatability Across Multiple Pieces

CNC metal engraving ensures that each piece is identical to the next, offering unmatched consistency and repeatability. Once a design is programmed into the machine, it can be replicated perfectly across hundreds or even thousands of pieces. This consistency is invaluable for industries like manufacturing and branding, where uniformity is critical for product quality and customer satisfaction.

Applications of CNC Metal Engraving

CNC metal engraving plays a critical role in various industrial sectors. In aerospace, precision is crucial for engraving serial numbers, logos, and part identification marks on metal components. Automotive manufacturers use CNC engraving for part labeling and custom engravings on car body parts, engines, and other components. In the machinery industry, CNC engraving ensures accurate identification, marking of specifications, and intricate details on heavy equipment.

Commercial Applications

In commercial sectors, CNC metal engraving is widely used for creating custom nameplates, signage, and branding materials. Businesses rely on CNC machines to engrave logos, product names, and other identifiers with high precision. In the awards industry, CNC engraving allows for the production of personalized trophies and plaques with intricate designs. Similarly, in the jewelry industry, CNC machines enable the creation of customized engravings on metal jewelry pieces, offering fine detailing and complex patterns.

Decorative and Artistic Applications

CNC metal engraving is also popular in the realm of art and decoration. Artists use CNC machines to create detailed metal artworks, sculptures, and personalized engravings for gifts, commemorative items, or home décor. The precision and ability to engrave on various metals make CNC machines ideal for crafting one-of-a-kind pieces, allowing for detailed designs and intricate patterns that add a personal touch to any project.

Materials Used in CNC Metal Engraving

CNC metal engraving is versatile and can be performed on various metals. Aluminum is lightweight, corrosion-resistant, and easy to engrave, making it a popular choice for custom signs and decorative items. Stainless steel is durable and resistant to wear, making it ideal for industrial applications and components that require high strength. Brass, known for its aesthetic appeal and workability, is often used in nameplates, awards, and decorative engravings. Copper, with its distinctive color and malleability, is used for artistic and intricate engravings, such as jewelry and artwork.

Factors to Consider When Choosing the Right Material for Engraving

When selecting a material for CNC metal engraving, factors such as hardness, corrosion resistance, and the intended use of the engraved piece should be considered. Softer metals like aluminum are easier to engrave, while harder metals like stainless steel may require specialized tools and slower speeds. Durability, surface finish, and cost are also important factors in making the right choice for the project.

Advantages of Using Specific Materials for Different Types of Engravings

Each metal offers unique benefits for specific applications. For example, aluminum’s light weight and ease of engraving make it perfect for detailed, low-volume production. Stainless steel is ideal for industrial components due to its strength, while brass and copper provide high-quality finishes for decorative and artistic engravings, ensuring long-lasting, visually appealing results.

The Metal Engraving Process

Step 1: Design Creation

The engraving process begins with design creation. Designers use CAD (Computer-Aided Design) software to craft intricate designs, logos, or text. These designs are then converted into machine-readable files through CAM (Computer-Aided Manufacturing) software, ensuring the CNC machine can accurately follow the pattern.

Step 2: Machine Setup

Once the design is ready, the next step is machine setup. The metal workpiece is securely mounted on the CNC machine’s table. The engraving tool is selected based on the material and design, and the CNC machine is calibrated for speed, depth, and precision. Proper calibration ensures optimal performance during the engraving process.

Step 3: Engraving

With everything in place, the engraving begins. The CNC machine follows the pre-programmed path, etching or carving the design into the metal. The engraving tool moves along precise axes, creating detailed patterns, logos, or text with consistent depth and clarity.

Step 4: Finishing

The final step is finishing. Once the engraving is complete, the workpiece is cleaned up. Excess material is removed, and the edges are smoothed. The engraving is then polished to achieve a high-quality finish, ensuring the design looks sharp and clear.

Challenges and Considerations

While engraving, challenges like material hardness, tool wear, and achieving consistent depth must be considered. Adjusting settings such as speed, feed rate, and cutting depth is essential for successful results.

How CNC Technology Simplifies the Process

CNC technology streamlines the engraving process by automating the steps, ensuring accuracy, repeatability, and high precision across multiple pieces. It reduces human error, enhances efficiency, and provides consistent, detailed engravings.

Troubleshooting and Tips for Successful Metal Engraving

Common Issues

CNC metal engraving can face challenges like tool wear, where the engraving tool loses sharpness, leading to rough cuts. Inaccurate designs may result from improper file conversion or machine calibration errors, causing deviations from the intended pattern.

Solutions and Tips

To prevent tool wear, ensure tools are regularly checked and replaced as needed. Using high-quality, durable tools and adjusting cutting speeds can help prolong their life. For accurate designs, always double-check the file conversion and calibration settings before starting the engraving. Keep the CNC machine properly maintained to avoid misalignment or malfunction. Additionally, use lubricants or coolants during engraving to reduce friction and prevent overheating, ensuring smoother and cleaner cuts.

Innovations in CNC Metal Engraving

CNC metal engraving has seen remarkable advancements in recent years. Modern CNC machines now feature high-speed spindles and advanced tool changers, allowing for faster and more efficient engraving. New materials for engraving tools, such as diamond-coated tips, ensure longer tool life and smoother cuts.

Integration of Automation and AI

Automation and artificial intelligence (AI) have significantly enhanced engraving processes. AI-powered CNC machines can optimize engraving paths, reduce errors, and automate routine tasks. This integration also allows for predictive maintenance, minimizing downtime and improving productivity.

Future Trends

Looking ahead, hybrid machines that combine multiple manufacturing processes, such as milling and engraving, are gaining popularity. These machines will enable greater flexibility and precision in complex designs. Additionally, multi-material engraving is emerging, allowing users to engrave different materials, such as metals and plastics, in a single setup. These innovations promise to further revolutionize the capabilities and applications of CNC metal engraving.

Conclusion

CNC machines have transformed the metal engraving process, offering precision, efficiency, and repeatability. Unlike traditional manual engraving, CNC technology automates the engraving process, reducing errors and enhancing productivity. From aerospace to jewelry, industries that require fine, intricate designs benefit immensely from the high accuracy of CNC machines.

The versatility of CNC machines allows for the engraving of a wide range of metals, including aluminum, stainless steel, brass, and copper. With specialized tools and advanced CAD/CAM software, CNC machines can produce complex patterns and ensure consistency across large-scale production runs.

As CNC technology continues to advance, the future of metal engraving looks promising with innovations like hybrid machines and multi-material engraving. These innovations will further enhance the capabilities and applications of CNC metal engraving, making it an invaluable tool for industries requiring high-quality, precision engravings.

In conclusion, CNC machines play a crucial role in revolutionizing metal engraving, providing unmatched precision, speed, and versatility.