XFD released a new successor popcorn machine in 2013. Since then, this generation of Electromagnetic Popcorn Machine has established XFD’s leader position all over the world. The electromagnetic heating technology redefines popcorn machines, this was verified these years.

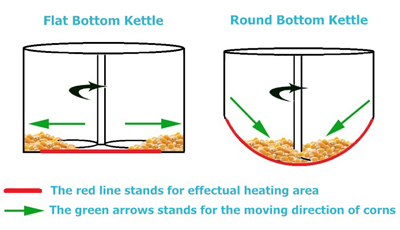

The traditional electric heating is a process in which electrical energy is converted to heat energy. Normally, the kettle of this type of popcorn machine has a flat bottom. This traditional energy-efficient process only converts 50%-60% of the electrical energy into effectual heat. So the heat losses by heat conduction process are high, it means the energy utilization is low and 40%-50% energy release to the air, which directly make the surroundings hot, and this is why we use the best heater tubes, wires and kettles, but after a long-term use, they will lead to creepage or short circuit. The traditional electric heating popcorn machine can make a kettle of popcorn in five minutes.

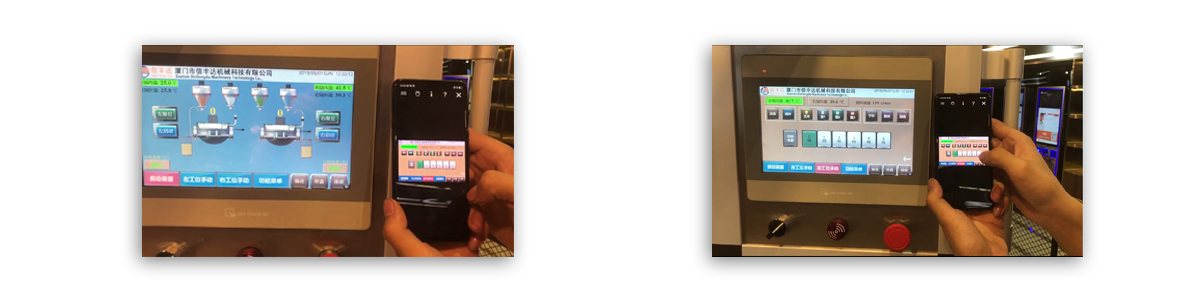

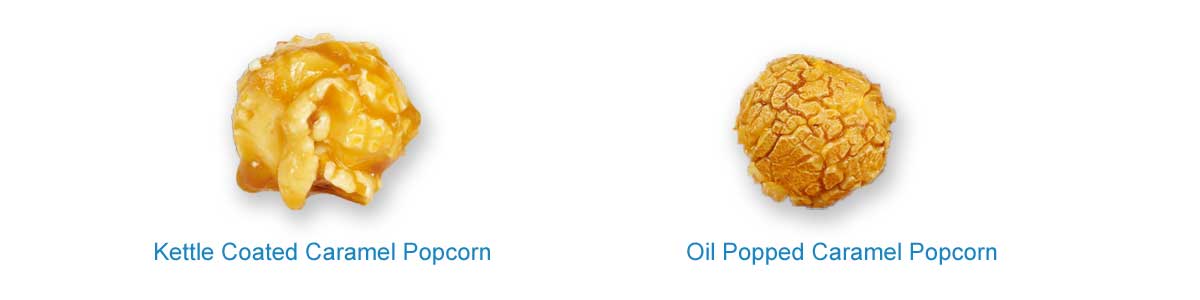

Nowadays, compared to the traditional electric heating, the advanced electromagnetic heating is a process in which electromagnetic energy is converted to heat. This uniquely energy-efficient process converts up to 97% of the electrical energy into effectual heat. The induction requires no warm-up or cool-down cycle, stand-by heat losses are reduced to a bare minimum. So the electric utilization is higher, saving energy. The electromagnetic heating popcorn machine can make a kettle of popcorn in three minutes, which is high productivity and 40% power saving. In addition, the electromagnetic working surface is made by heat insulation material, all the wires and other main parts are under the surface (far away from the hot kettle & hot surroundings), therefore the parts have a longer working life. In order to max the energy utilization, the bottom of electromagnetic popcorn machine’s kettle is designed to be round (Ball Shape), this is a patent for utility medal of XFD.

Why do we design the round

bottom kettle? Compared to the flat bottom kettle, the round onehas big

advantages: The round bottom kettle could

avoid the centrifugal effect and ensure all the corns are in the middle of the

bottom (the effectual heating area) and well burst while the stirring rod rotating in the kettle, this directly influences

the production yield. The pelletizing ratio for jumbo (ball shape) is up to 90%-91%, which the traditional machine is only 80%-86%,

and the production yield is up to 99%. Beside, easily equipped with automatic

kettle-cleaning function by using the water droplets’ self-flow characteristic

and the stirring rod, these make it easy to clean. Both the stirring rod in the

kettle and the electromagnetic working surface don’t touch the round bottom (2mm

space) to avoid the kettle being abraded, therefore we

could make the round kettle with the stainless steel of 3mm thickness, which is

easier to operate and transport.

onehas big

advantages: The round bottom kettle could

avoid the centrifugal effect and ensure all the corns are in the middle of the

bottom (the effectual heating area) and well burst while the stirring rod rotating in the kettle, this directly influences

the production yield. The pelletizing ratio for jumbo (ball shape) is up to 90%-91%, which the traditional machine is only 80%-86%,

and the production yield is up to 99%. Beside, easily equipped with automatic

kettle-cleaning function by using the water droplets’ self-flow characteristic

and the stirring rod, these make it easy to clean. Both the stirring rod in the

kettle and the electromagnetic working surface don’t touch the round bottom (2mm

space) to avoid the kettle being abraded, therefore we

could make the round kettle with the stainless steel of 3mm thickness, which is

easier to operate and transport.

In short, the Electromagnetic Popcorn Machine is easier to clean up and being maintained, operation safety, cost saving, energy conservation and stable performance. The choice of a new generation: Electromagnetic Popcorn Machine. It is really suitable for retail, theaters, schools and more commercial places. It will exceed your expectation.