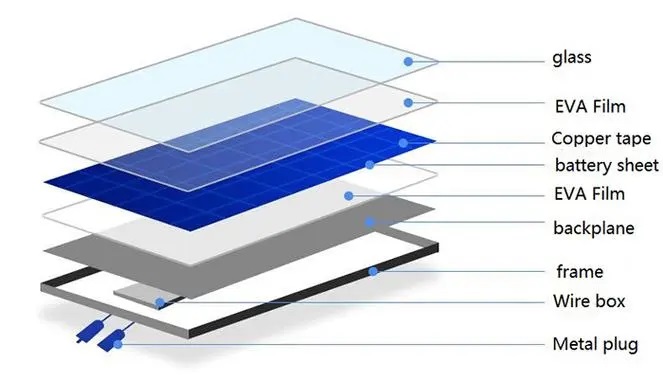

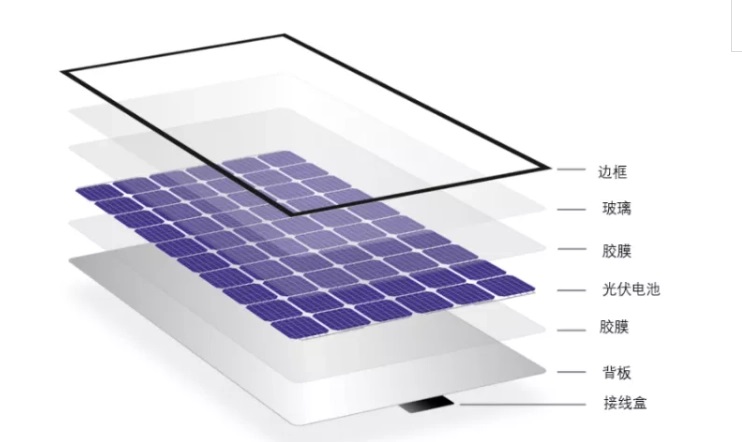

Solar Module EVA Film Introduction 1

In order to improve the power generation efficiency of solar cell modules, provide protection against the loss caused by environmental climate change, and ensure the service life of solar modules, EVA plays a very important role. EVA is non-adhesive and anti-adhesive at room temperature. After hot pressing under certain conditions during the solar cell packaging process, EVA will produce melt bonding and adhesive curing. The cured EVA film becomes completely transparent and has quite high light transmittance. The cured EVA can withstand atmospheric changes and has elasticity. The solar cell wafer is wrapped and bonded with the upper glass and lower TPT by vacuum lamination technology.

Basic functions of EVA film:

1. Secure the solar Cell and connecting circuit wires to provide cell insulation protection

2. Perform optical coupling

3. Provide moderate mechanical strength

4. Provide a heat transfer pathway

EVA Main features:

1. Heat resistance, low temperature resistance, moisture resistance and weather resistance

2. Good followability to metal glass and plastic

3. Flexibility & Elasticity

4. High light transmission

5. Impact resistance

6. Low temperature winding

Thermal conductivity of solar cell related materials: (K value of thermal conductivity at 27 ° C (300'K))

Description: EVA is used for the combination of solar cells as a follow-up agent, because of its strong follow-up ability, softness and elongation, it is suitable for joining two different expansion coefficient materials.

Aluminum: 229 ~ 237 W/(m·K)

Coated aluminum alloy: 144 W/(m·K)

Silicon wafer: 80 ~ 148 W/(m·K)

Glass: 0.76 ~ 1.38 W/(m·K)

EVA: 0.35W /(m·K)

TPT: 0.614 W/(m·K)

EVA appearance inspection: no crease, no stain, smooth, translucent, no stain edge, clear embossing

EVA material performance parameters:

Melting index: affects the enrichment rate of EVA

Softening point: The temperature point at which EVA begins to soften

Transmittance: There are different transmittance for different spectral distributions, which mainly refers to the transmittance under the spectral distribution of AM1.5

Density: density after bonding

Specific heat: the specific heat after bonding, reflecting the size of the temperature increase value when the EVA after bonding absorbs the same heat

Thermal conductivity: thermal conductivity after bonding, reflecting the thermal conductivity of EVA after bonding

Glass transition temperature: reflects the low temperature resistance of EVA

Breaking tension strength: The breaking tension strength of EVA after bonding reflects the mechanical strength of EVA after bonding

Elongation at break: the elongation at break at EVA after bonding reflects the tension of EVA after bonding

Water absorption: It directly affects the sealing performance of battery cells

Binding rate: The binding rate of EVA directly affects his impermeability

Peel strength: reflects the bond strength between EVA and peel

EVA reliability test purpose: to confirm the weather resistance, light transmission, bonding force, ability to absorb deformation, ability to absorb physical impact, damage rate of pressing process of EVA... Let's wait.

EVA aging test equipment and projects: constant temperature and humidity test chamber (high temperature, low temperature, high temperature and high humidity), high and low temperature chamber (temperature cycle), ultraviolet testing machine (UV)

VA Model 2: Glass /EVA/ conductive copper sheet /EVA/ glass composite

Description: Through the on-resistance electrical measurement system, the low resistance in EVA is measured. Through the change of the on-resistance value during the test, the water and gas penetration of EVA is determined, and the oxidation corrosion of copper sheet is observed.

After three tests of temperature cycle, wet freezing and wet heat, the characteristics of EVA and Backsheet change:

(↑ : up, ↓ : down)

After three tests of temperature cycle, wet freezing and wet heat, the characteristics of EVA and Backsheet change:

(↑ : up, ↓ : down)

|

EVA: |

Backsheet: |

| Yellow↑ |

Inner layer yellow ↑ |

|

Cracking ↑ |

Cracks in the inner layer and PET layer ↑ |

|

Atomization ↑ |

Reflectivity ↓ |

|

Transparency ↓ |

|