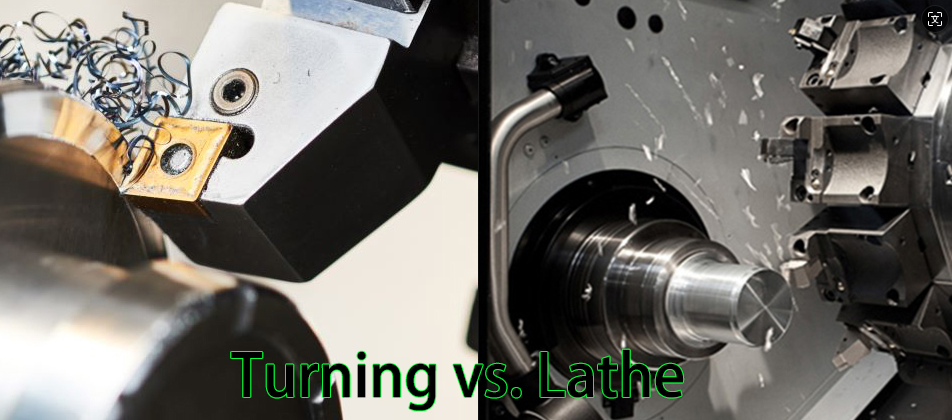

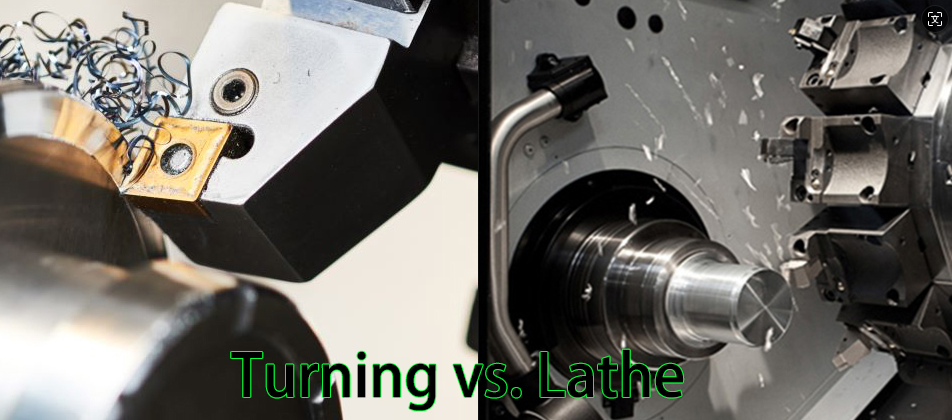

In the world of machining, lathes, and turning centers play a vital role in shaping metal and other materials into precision parts. While both machines perform similar functions—rotating a workpiece to perform cutting, drilling, or milling tasks—their capabilities, complexity, and applications can differ significantly.

As advancements in CNC (Computer Numerical Control) technology evolve, manufacturers are faced with choosing between the simplicity of a traditional lathe and the advanced automation of a turning center.

This article provides a comparison of turning centers and lathes, outlining their features, functionalities, and ideal use cases. By the end, you’ll have a clear understanding of which machine suits your specific manufacturing needs.

So, let’s begin!

What is a Lathe?

A lathe is one of the oldest and most versatile machines used in manufacturing. At its core, a lathe rotates a workpiece on its axis while various tools are applied to cut, shape, or drill the material. Over centuries, the lathe has evolved from rudimentary designs to highly sophisticated machines that play a pivotal role in modern industry.

Today, lathes can range from traditional manual models to advanced CNC (Computer Numerical Control) machines capable of producing intricate and precise parts.

Traditional vs. Modern Lathes

Traditional lathes, also known as manual lathes, require the operator to manually adjust the cutting tools and guide the workpiece to achieve the desired shape. These machines are typically used for simple operations like turning cylindrical objects, threading, and drilling. While still widely used, they require skilled operators and are best suited for low-volume production or smaller projects.

Modern lathes, particularly CNC lathe machines, are highly automated and can handle more complex tasks with little human intervention. These machines are controlled by pre-programmed software that allows for precise, repeatable operations. CNC lathes are commonly used in high-volume production environments where accuracy and efficiency are critical.

Types of Lathes

1. Manual Lathes: These machines rely on the operator’s skill to manually adjust the cutting tool, speed, and feed rate. They are ideal for smaller, simpler projects but require greater hands-on expertise.

2. CNC Lathes: CNC lathes are automated and controlled by computer programs, enabling highly accurate and repeatable cuts. They are often used for large-scale production or complex components that require precision beyond manual capabilities.

Core Components

Every lathe, whether manual or CNC, shares several essential components:

● Headstock: The part of the lathe that holds the motor and the drive mechanism. It houses the spindle, which rotates the workpiece.

● Spindle: Located within the headstock, the spindle holds and rotates the workpiece, ensuring it is aligned with the cutting tool.

● Tool Post: This is where the cutting tools are mounted. The tool post can be adjusted to move the cutting tool toward or away from the workpiece.

● Chuck: The chuck is the gripping device that holds the workpiece securely in place while it rotates.

What is a Turning Center?

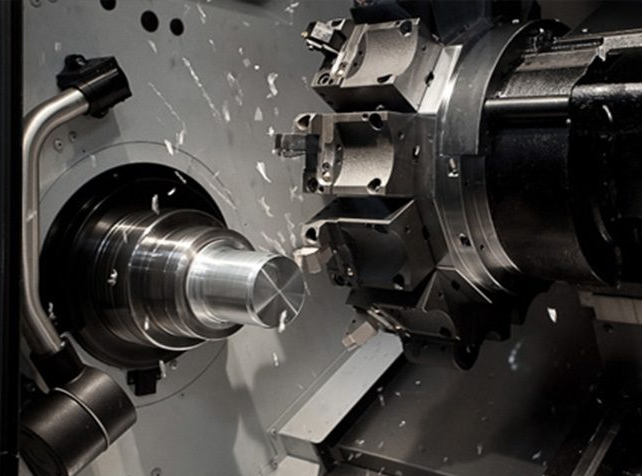

A turning center is an advanced machine tool designed to perform a wide variety of tasks beyond simple turning operations. While similar to a lathe in its basic function of rotating a workpiece to perform cutting, turning centers are equipped with enhanced automation, multi-axis capabilities, and additional features that allow them to handle more complex machining tasks.

These machines are highly automated and can complete multiple processes—such as turning, milling, drilling, and tapping—within a single setup, reducing production time and increasing efficiency.

Key features of a turning center include CNC control, live tooling, automatic tool changers, and multi-axis movement. The ability to perform various tasks in one machine means turning centers are ideal for high-volume production environments where efficiency and precision are essential.

Modern Developments and Automation

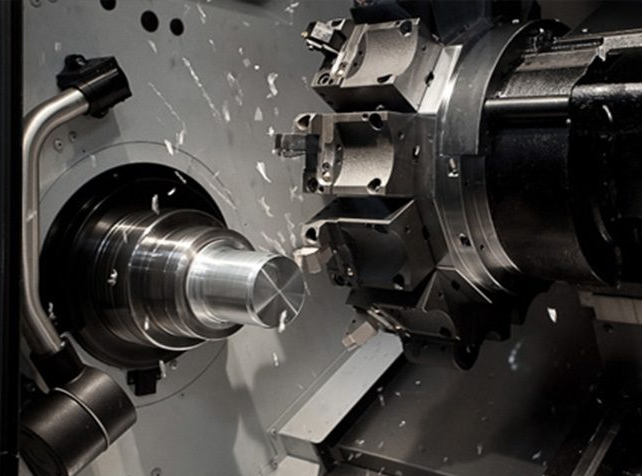

Modern turning centers have significantly evolved from traditional lathes due to advancements in CNC technology and automation. With computer-aided design (CAD) and computer-aided manufacturing (CAM) integration, turning centers can execute complex machining tasks with minimal operator input.

Automation has enabled turning centers to process multiple parts in a single run, drastically reducing setup time and improving production speed. The inclusion of robotic arms for material loading and unloading further increases their productivity.

Additionally, modern turning centers often feature live tooling—tools that are powered and capable of performing milling, drilling, or other operations while the workpiece is stationary. This allows turning centers to produce more intricate and varied parts without the need to transfer the workpiece to another machine.

Differences from Traditional CNC Lathes

While both turning centers and CNC lathes are used for machining cylindrical parts, turning centers offer more advanced technology and capabilities. A traditional CNC lathe is designed primarily for turning operations, which involves rotating the workpiece and cutting material to create cylindrical shapes.

In contrast, turning centers are multi-tasking machines that can perform milling, drilling, boring, and even threading operations alongside turning.

The key differences include:

● Multi-Axis Capabilities: CNC lathes typically operate on two axes (X and Z), whereas turning centers can operate on multiple axes, including Y and C axes, allowing for more complex geometries.

● Live Tooling: Turning centers often come with live tooling that allows them to perform additional functions like milling, drilling, and tapping without requiring separate machines.

● Automatic Tool Changers: Unlike CNC lathes, which may require manual tool changes, turning centers use automatic tool changers (ATC) to switch between tools during operation, enabling continuous, uninterrupted machining.

These advancements make turning centers more suitable for complex parts and high-volume production where speed, accuracy, and flexibility are critical.

Types of Turning Centers

Turning centers come in various configurations to suit different machining needs. The two primary types are:

1. Horizontal Turning Centers: In these machines, the spindle is oriented horizontally. They are the most common type and are used for tasks where gravity assists in removing chips from the work area. Horizontal turning centers are ideal for longer workpieces and are widely used in industries like automotive and aerospace.

2. Vertical Turning Centers: In vertical turning centers, the spindle is positioned vertically, and the workpiece is mounted on a horizontal table. These machines are often used for larger, heavier parts that are difficult to hold in a horizontal orientation. Vertical turning centers are typically used in industries where large diameters and heavy parts, such as gear manufacturing, are common.

Within these categories, turning centers can also be classified based on the number of turrets they have:

● Single-Turret Turning Centers: These machines have one tool turret, which limits the number of tools available at any given time. However, they are still capable of performing multi-tasking operations due to live tooling.

● Multi-Turret Turning Centers: Machines with two or more turrets allow for even greater versatility. They can use multiple tools simultaneously, increasing machining efficiency by reducing tool change times and allowing for parallel operations on the same workpiece.

Capabilities and Functions

Turning centers are versatile machines capable of performing a wide range of tasks beyond basic turning. Their multi-tasking abilities set them apart from traditional lathes. Some of their key functions include:

● Turning: Like a lathe, turning centers perform traditional turning operations, where a rotating workpiece is shaped by cutting tools.

● Milling: Equipped with live tooling, turning centers can perform milling operations, which involve removing material from the workpiece using rotating cutting tools, often to create flat surfaces or intricate shapes.

● Drilling and Tapping: Turning centers can drill holes into the workpiece, as well as tap threads, eliminating the need for separate drilling or tapping machines.

● Boring and Grooving: Precision internal machining such as boring (enlarging holes) and grooving (cutting channels) can be performed without needing to transfer the workpiece to another machine.

● Threading: Turning centers can also cut threads for bolts or screws, combining multiple operations into one seamless process.

Key Differences Between a Lathe and a Turning Center

Complexity and Automation

Lathes, particularly manual and basic CNC models, are simpler machines that focus on turning operations, often requiring manual input or basic CNC programming. In contrast, turning centers are highly automated, featuring advanced CNC control, enabling complex operations with minimal operator intervention.

Multi-Functionality

Lathes are primarily designed for turning tasks, while turning centers offer multi-functionality, capable of performing turning, milling, drilling, and tapping in a single setup. This versatility makes turning centers ideal for complex, multi-step machining processes.

Axes of Movement

Lathes typically operate on two axes (X and Z), limiting their movement and machining options. Turning centers, on the other hand, often feature additional axes, such as the Y-axis and C-axis, along with live tooling, allowing for more intricate part geometries and machining versatility.

Tooling and Setup

In a traditional lathe, tool changes are often manual or semi-automatic, which can increase downtime. Turning centers, however, are equipped with automatic tool changers (ATC), enabling faster, seamless transitions between tools, improving overall production speed and reducing setup time.

Cycle Time and Efficiency

Turning centers excel in efficiency, especially when handling complex parts. Their ability to perform multiple operations without the need for transferring the workpiece between machines reduces cycle time, making them more suitable for high-volume and complex part production.

Cost and Maintenance

Lathes typically have a lower initial investment due to their simpler design and limited automation, making them more budget-friendly for small-scale operations. In contrast, turning centers are more expensive, reflecting their advanced capabilities and automation features.

Maintenance requirements for lathes are minimal, involving basic upkeep such as lubrication and tool adjustments. Turning centers, however, demand more frequent and specialized maintenance due to their complexity.

While turning centers reduce labor and improve efficiency, their operational costs, including higher energy consumption and maintenance, are greater, but they can offer significant long-term cost savings in high-volume production.

Precision and Accuracy

Lathes offer adequate accuracy for simpler machining tasks but are limited in maintaining tight tolerances. Turning centers, with their multi-axis capabilities and advanced CNC control, provide superior precision, ensuring tighter tolerances for complex parts.

The quality of surface finishes also differs significantly. While lathes can produce smooth finishes, turning centers excel in delivering consistent, high-quality results with greater repeatability, thanks to their automated tooling and advanced functions.

For industries where precision and surface quality are critical, such as aerospace or medical device manufacturing, turning centers are the preferred choice over standard lathes.

Which Should You Choose?

Factors to Consider

When deciding between a lathe and a turning center, several factors should be evaluated. Consider your production volume—if you have high-output demands, a turning center’s automation can boost efficiency. The complexity of the parts you manufacture is also crucial; for simpler tasks, a lathe may suffice, but intricate components benefit from a turning center’s precision.

Budget is another key consideration, as lathes have lower initial costs. Lastly, automation needs will influence your choice: turning centers are better for highly automated, multi-task processes, whereas lathes are more manual.

Advantages of Lathes

Lathes offer simplicity, making them easier to operate and maintain, which reduces both upfront and ongoing costs. Their straightforward design is ideal for smaller, less complex parts that don’t require intricate machining processes.

For businesses with lower production volumes or budget constraints, lathes provide a reliable solution without the need for advanced features or multi-tasking capabilities.

Advantages of Turning Centers

Turning centers shine in multi-functionality, capable of performing turning, milling, drilling, and more in a single setup. They are highly productive, reducing cycle time and increasing output, especially for complex parts. With their advanced automation and multi-axis movement, turning centers are ideal for industries requiring high precision and efficiency in large-scale production, making them a superior choice for demanding applications.

Here’s the table that contains the key differences between Lathe and Turning Center.

|

Feature

|

Lathe

|

Turning Center

|

|

Primary Function

|

Focuses on basic turning operations.

|

Capable of turning, milling, drilling, and more.

|

|

Complexity

|

Simpler machinery with manual or basic CNC control.

|

More complex with advanced CNC control and automation.

|

|

Axes of Movement

|

Typically operates on two axes (X, Z).

|

Offers multi-axis movement (X, Y, Z, C), including live tooling.

|

|

Tooling System

|

Manual or semi-automatic tool changes.

|

Equipped with automatic tool changers for faster transitions.

|

|

Precision

|

Adequate for simpler parts with moderate accuracy.

|

High precision, suitable for intricate and complex parts.

|

|

Production Volume

|

Suitable for low to medium production volumes.

|

Ideal for high-volume, continuous production.

|

|

Best Use Cases

|

Ideal for simple, cylindrical parts.

|

Suited for complex parts requiring multi-tasking capabilities.

|

That’s A Wrap!

In choosing between a lathe and a turning center, your decision should be guided by production needs, part complexity, budget, and automation requirements. Lathes offer simplicity and cost-effectiveness for less intricate tasks while turning centers excel in multi-tasking and precision for complex parts and high-volume production.

Frequently Asked Questions

What is the main difference between a lathe and a turning center?

A lathe is simpler and designed for basic turning tasks, while a turning center offers advanced multi-functionality, handling complex machining operations.

Which is better for high-volume production, a lathe or a turning center?

A turning center is better suited for high-volume production due to its automation and ability to perform multiple tasks in one setup.

Are turning centers more expensive to maintain than lathes?

Yes, turning centers typically have higher maintenance costs due to their complex features and advanced automation.