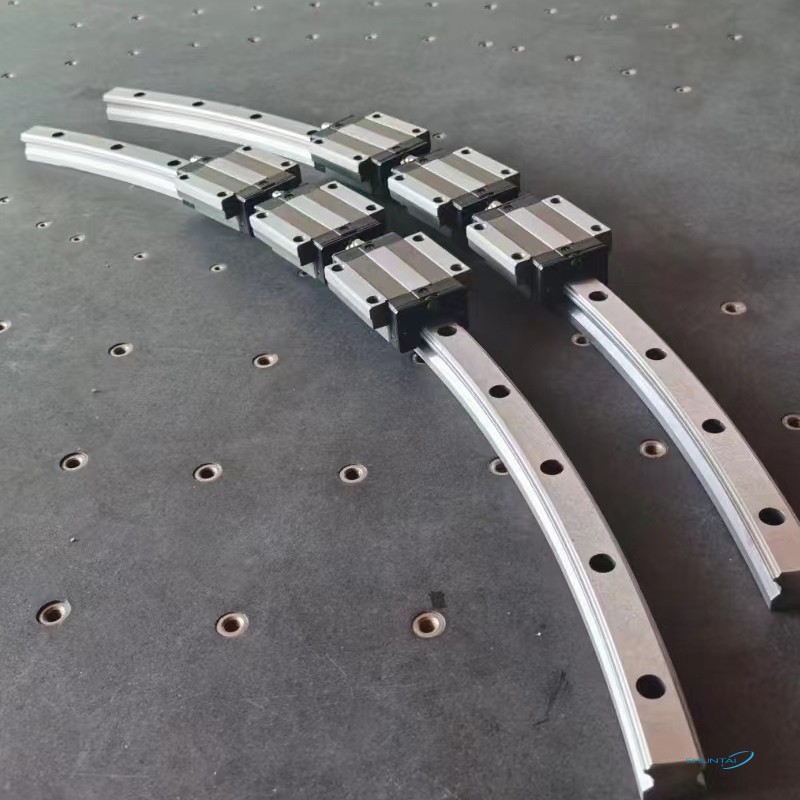

Micro guide rails refer to guide rail systems with a width of less than 25mm. They are usually composed of guide rails and sliders. They are small in size, light in weight, high in precision, low in noise, and long in life. They are mainly used to support and position optical components such as mirrors, lenses, filters, etc. Micro guide rails help improve the performance and stability of equipment by providing high-precision motion control. In optical instruments, the role of micro guide rails is particularly critical. Next, let's take a look at the role of micro guide rails in optical instruments.

1. Support and positioning: Micro guide rails can ensure the precise position and stability of optical components. They provide a reliable support structure that enables optical components to be fixed in the desired position, thereby maintaining the stability of the optical system.

2. High-precision guidance: In scenes such as microscopes, optical microscopic imaging systems, and laser processing equipment, tiny-sized motion and positioning are critical to imaging quality and processing accuracy. By fine-tuning the position of the guide rail, the position and direction of the optical component can be fine-tuned to achieve the desired optical effect.

3. Reduce friction and vibration: Friction and vibration can have a negative impact on the imaging and measurement of optical instruments, reducing their accuracy and stability. Micro guide sliders have excellent low friction characteristics and vibration reduction capabilities, which can effectively reduce the impact of friction and vibration, improve the imaging quality and measurement accuracy of optical instruments, especially in applications that require a stable optical path or precise measurement, which is essential for accurately controlling the position and movement of optical components.

4. Automation: Micro guides can be integrated with automation systems to achieve high-speed, high-precision and automated motion control of optical components. This enables optical instruments to achieve higher efficiency and accuracy, as well as a wider range of applications.

The role of micro guides in optical instruments is support and motion control. With its high precision and high stability, it provides a stable optical path and precise position of optical components. With the continuous advancement of optical instrument technology and the continuous expansion of application areas, micro guides will play a more important role in the future.