Blades maintenance

Why the cutting blades need the maintenance?

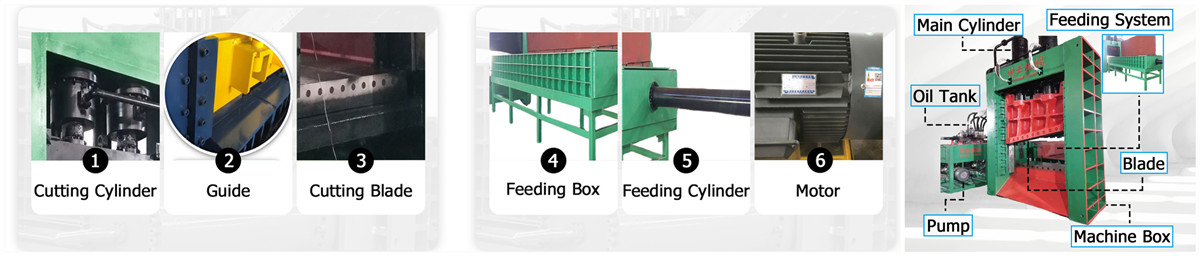

The cutting blades play a very important role in the scrap metal shears, no matter the gantry shear, the container shear, the tiger shear orthe alligator shear. Good condition of the cuuting the blades mean the scrap metal shear will have the high cutting force and high production.

How to maintain the cutting blades?

- Before turning on the scrap metal shear, press the smooth chart to request time, fixed -point, and quantitative heat oil. The smooth oil should be cleaned and free of precipitation. Persist in adding an appropriate amount of light oil, insist on cleaning the appearance of the blades, and improve the abrasion resistance of the blades.

- When using the scrap metal shear, it is necessary to operate the scrap metal shear under the guide of the "Operation Regulations on the Operation of Scrap Steel Shear Machines" and correctly use the blades.

- The blades must always insist on cleaning rust -proof oil. Remnant blades should choose a cool and boring central storage. To avoid rust of the blades, apply a layer of anti -rust oil on the blade that was once opened. The boring center ensures that the blade is not rusted.

- Regularly check that the using blades of the wear status. The blade is severely changed in time and submitted to the appliance supplement.

- 10 minutes before get off work every day, stop scrubbing and clean the blades, and refuel smoothly. It is necessary to insist on cleaning the state. The central center without paint should pay attention to avoid rust, and regularly work for the switch and other quality.